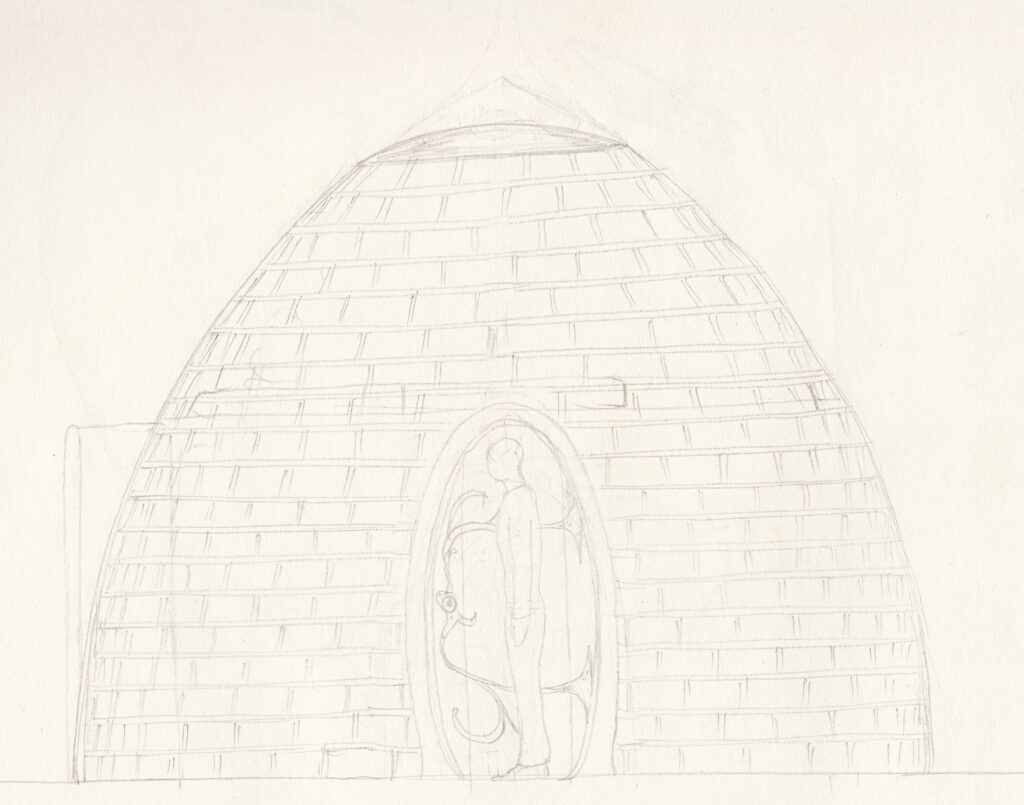

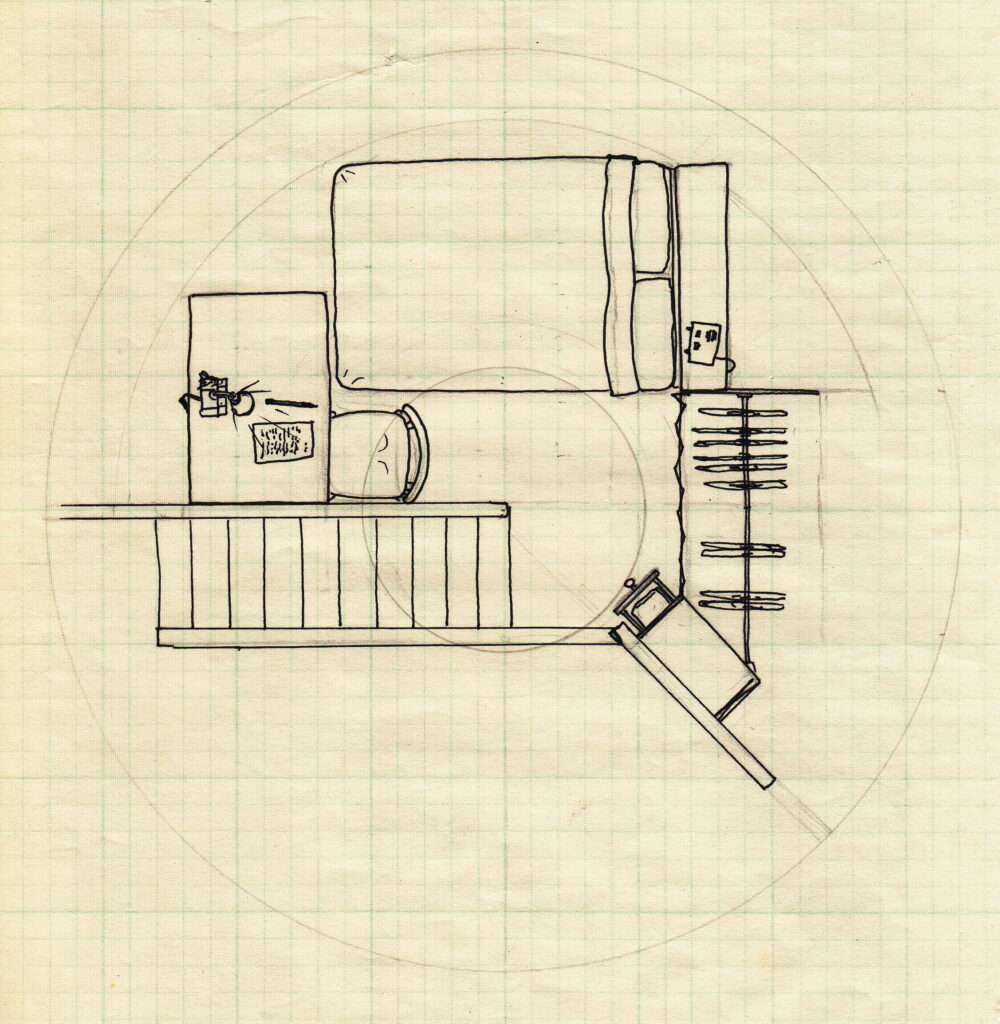

An early rendition of a 16 foot diameter Beehive shaped dome.

Years ago I was interested in Geodesic domes until, being a drywall finisher, I had the misfortune to mud one of these beasts. Luckily the home owner, already finding the expenses way too high for this project, allowed us to use a rubber trowel to coat the many ceiling off-angles. Thank God!

Recently I had the privilege to talk with Lloyd Kahn, the first to take Buck Minster Fuller’s Geodesic designs to the building industry, publishing build plans for Geodesic stick-built homes back in the early 70’s. He told me of his epiphany one day while high on mescaline, that building a Geodesic dome home was actually a bad idea, and promptly called his publisher to stop further sales and distribution of his two books. Good call Lloyd! Money is one thing, but your reputation is another. That being said, I still like the dome idea. Inside a dome is a perspective very different than our traditional block roomed homes. A dome also holds up very well to extreme wind conditions.

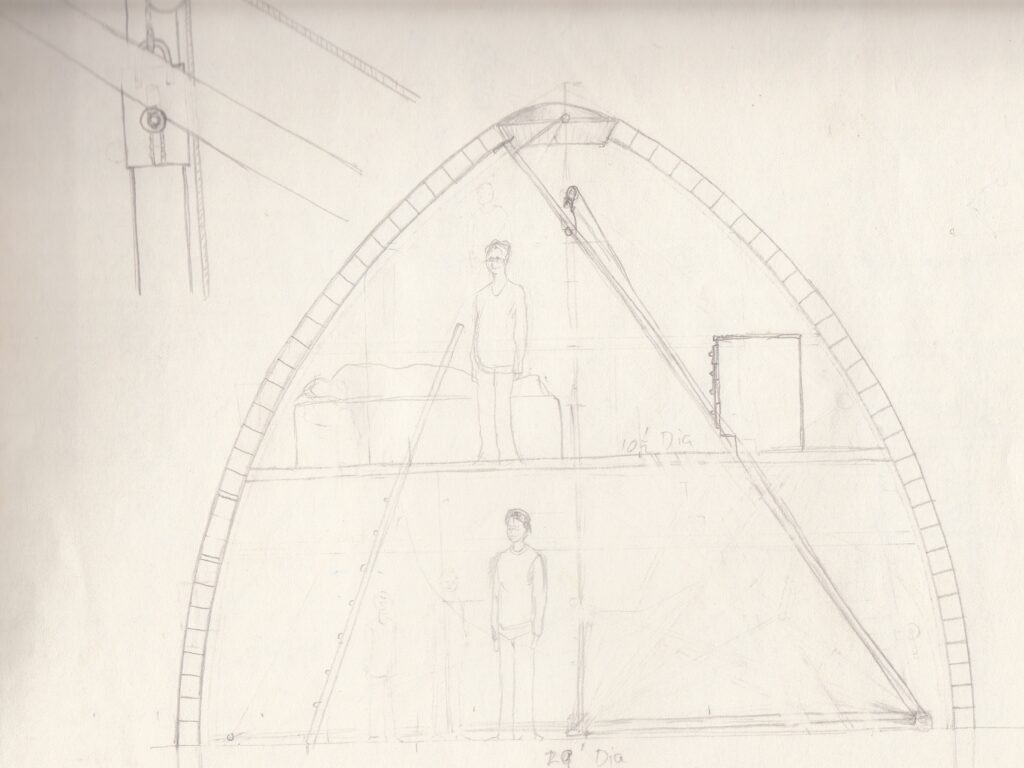

20 foot diameter cinder block dome.

This block placing jig idea started when I was doodling with my drafting compass. It’s basically an elaborate way to help a mason set blocks. The end result would be a very strong beehive shaped non-framed structure that only needs skimming with a finish coat and weather proof sealant. What’s not to like? If cinder blocks were used, shredded recycled packing styrofoam could be added to the hollow sections of the blocks. In this first version I envisioned a cable supported central pole in the center of the round foundation with a cable controlled sleeve to help raise and lower the block placement arm (detail upper left corner).

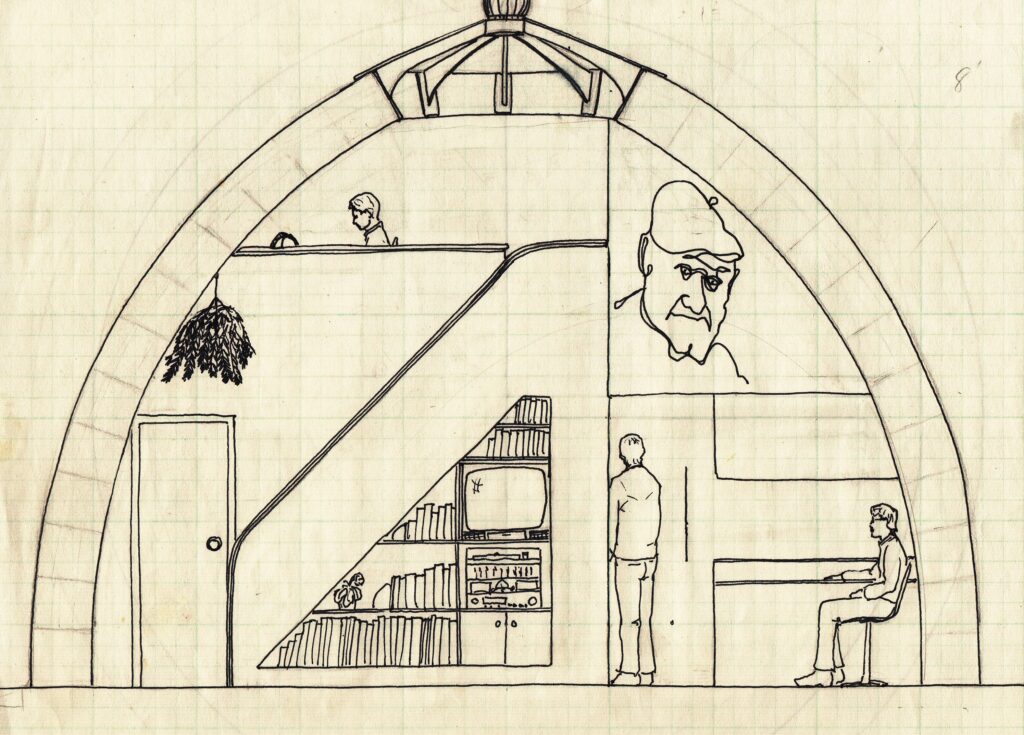

Depiction of 24 foot diameter straw bale house.

When I first thought of the idea I was thinking of using straw bales, but due to their compression I opted to use cinder block as the favored building material, but brick could also work as well. Maybe bottles? Hmmm.

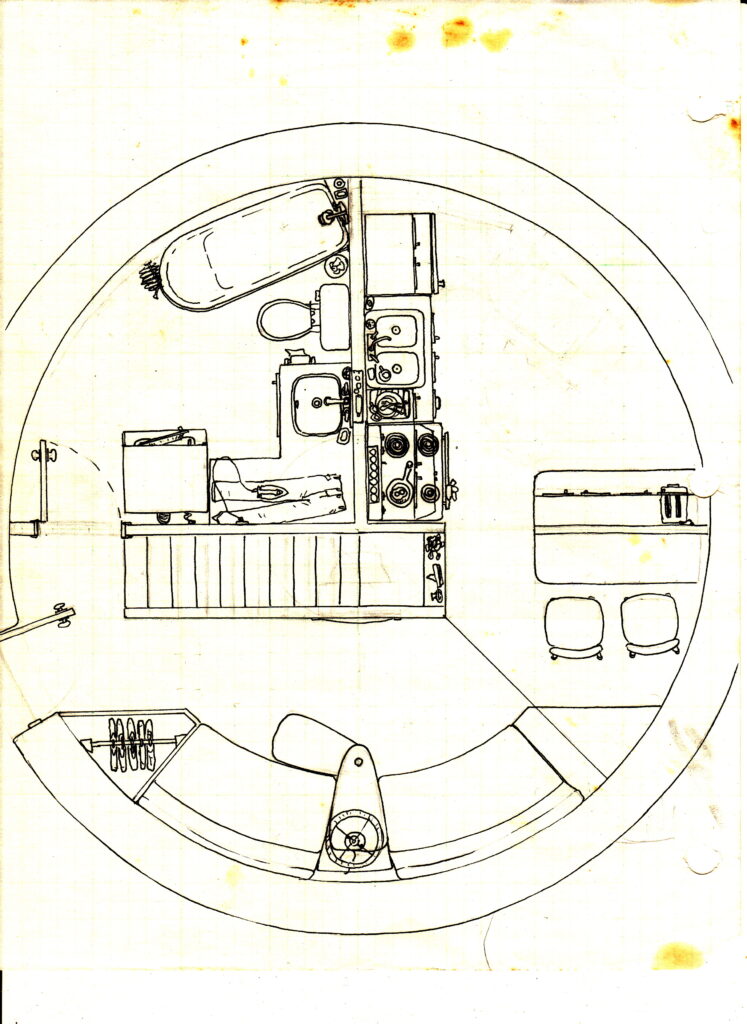

Here’s a downward view of the main floor.

Bedroom loft.

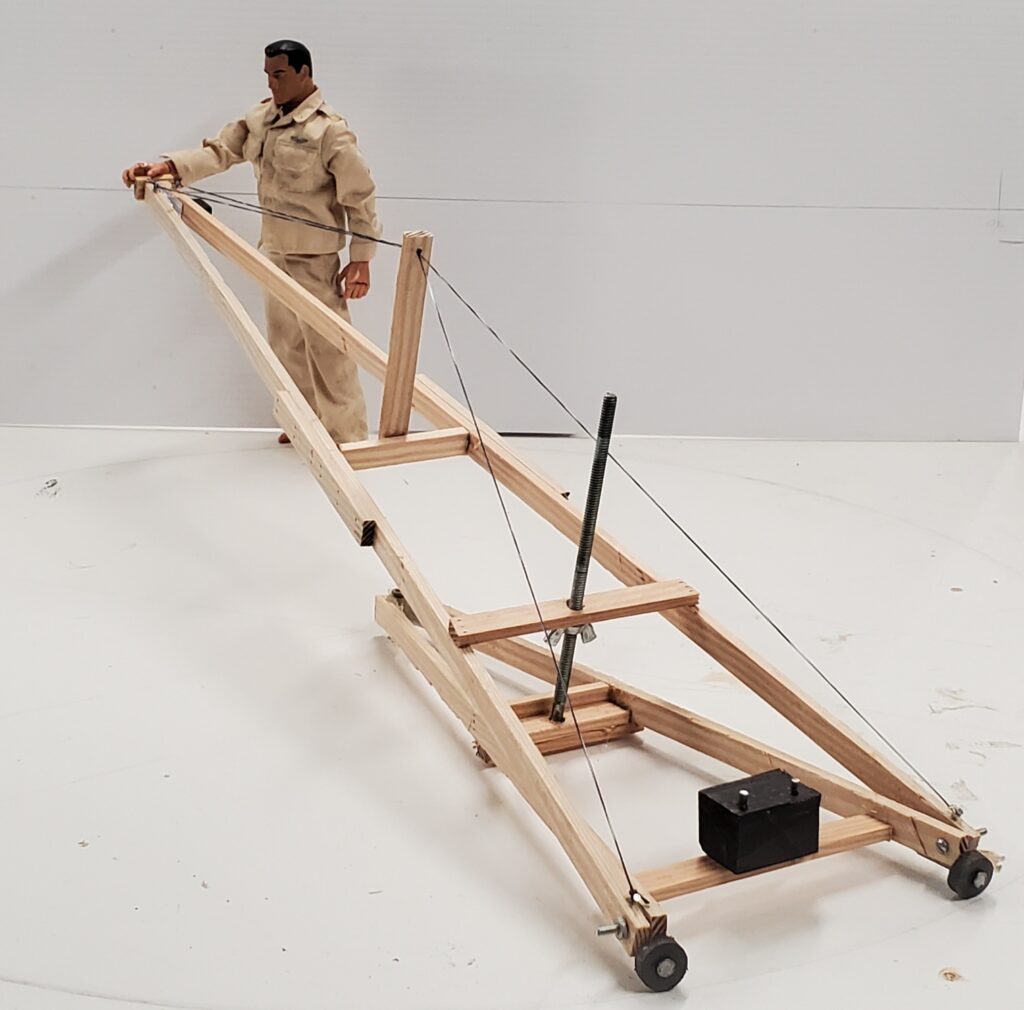

Block placement model

The first overbuilt version I had in mind had a 12v battery powered drive wheel to assist in rotating the jig around a central axis. The power on-off switch to incrementally move the jig was located near the end of the boom for the block layer to easily operate.

The triangulation of the frame was intended to keep the jig from twisting and moving around. I hadn’t figured out how to raise or lower the arm yet, but a manual hydraulic scissor jack was a possibility.

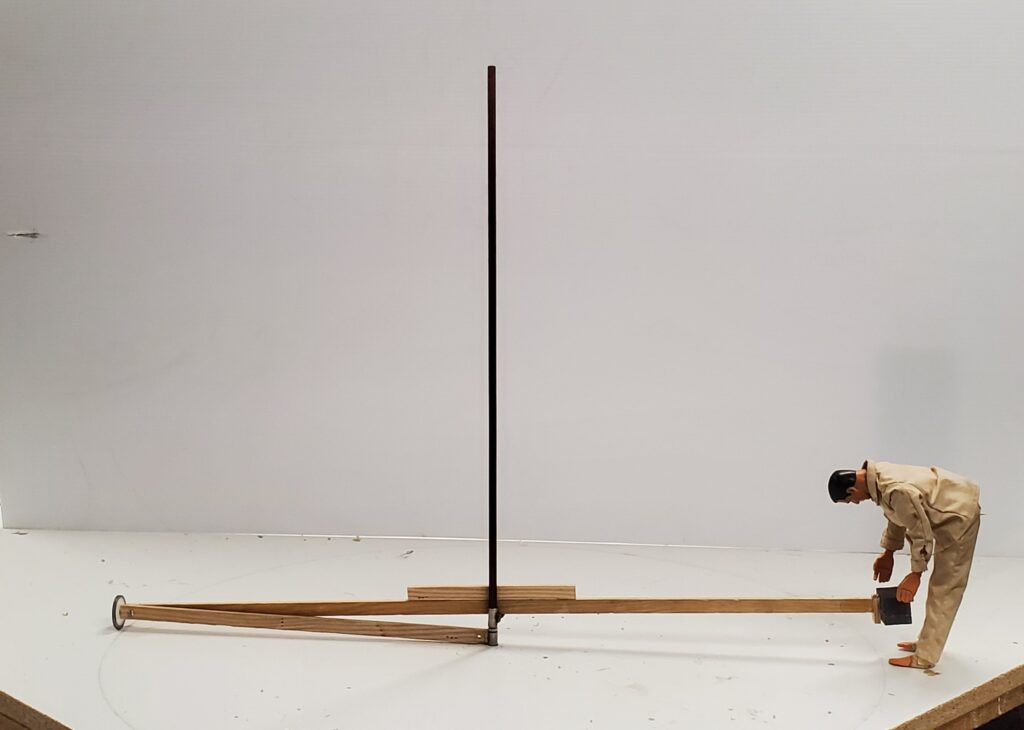

Second version

After consulting with a fellow engineer, I decided to lighten the jig and eliminate the need for a power assisted wheel. Having a central pole goes back to my first idea, but without the use of a cable for pole support or to raise and lower the pole. Here I kept it simple and let the worker lift the arm by hand to relocate the height.

I can see the mason laying the first and consecutive block courses up to this height on the outside of the dome, then switching to the inside where scaffold could be used.

On this version I have a lower sleeve (zip tie) that supports the arm guide sleeve above it. This could be slid up and down by the operator and clamped to the pole, similar to a bicycle quick release seat post clamp. The upper sleeve would rotate around the lower fixed sleeve and have a 3″ bolt welded horizontally to the side, acting as an axle for a 3″ diameter guide wheel for supporting the arm. It would have 6″ disks on either side of the wheel which would loosely sandwich the arm. The disks would help in keeping the arm against the pole and to help move the wheel assembly with the arm when rotated.

The wheel was enlarged to an 8″ diameter wheel. This would help in moving the jig with a nudge from the block setter.

The black square represents a cinder block laid flat against the block placement plate. This fixture was designed ONLY to help position a block, not to carry a block.

I’m tempted to make a brick Pizza oven or funky foam lamp shade to test out my theory before making a full scale version for a dome, which I probably won’t, as space is limited on my little lot.

If this idea interests you at all, and you plan to try making a jig and build a dome with a jig of this design, please contact me first. I will not be held responsible or liable if you or someone working with you is injured or killed while using this jig idea. There have been recorded deaths of workers making DIY brick laid domes where the roof suddenly collapse on workers before the final brick is layed. Use extra caution when using this method. Check out Youtube to see how folks in the East lay their brick domes. After watching one of these videos, I realized it was possible, but these folks have been building brick dome structures for many generations and know the tricks of this dangerous trade.