I’ve been wanting to have a powered bicycle (with usable pedals) to tow my bicycle campers with. Electric to me is too much money and a hassle, plus on a long journey when the juice runs out you’re stuck pedaling. I favor the old briggs motors. They’re 4 cycle (no need to add oil to the gas) dependable, cheap (I got mine off of a grass edger for $30) and easy to work on. This 2hp model keeps me under the 49cc, the legal requirement for road use, at least in the state of Washington. I’m allowed to putt around without the need of a registration, license plate or insurance. All I need is a drivers license. Max speed allowed is 30 mph which is about the max for this set-up.

Unfortunately the gearing on this set-up is too high for towing a trailer, so I’m still thinking of a different design to meet my needs. It’s still a fun ride. I do have to assist when going up steep hills but on the flats the bike goes a comfortable 27 mph. The motor was positioned as low as possible and a comfortable distance from my butt. I wanted air to be able to circulate around me to cool the engine. This set-up does place the motor high making for a top heavy vehicle, but once you get going it’s not a problem. Hitting severe bumps does jolt the rear wheel a bit due to the dead weight of the 23 pound motor. When encountering a bump I stand on my pedals. This helps some.

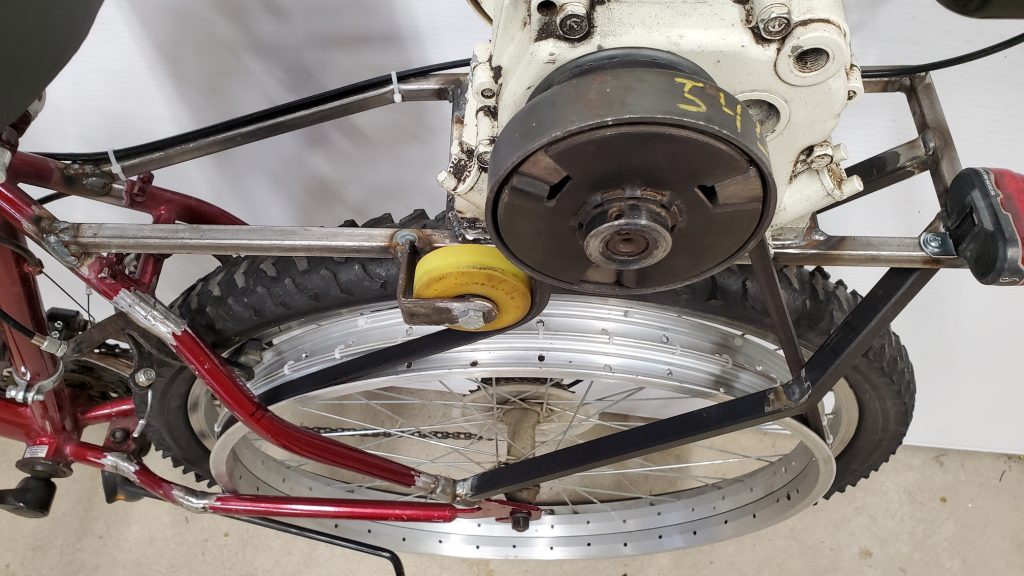

I used two 24″ bicycle wheel rims zip tied together for the large pulley. This was then zip tied to the 26″ rear wheel rim. As weak as a little zip tie seems, I haven’t had any issues yet. I had to do some alterations to the frame to accommodate the extra width of the pulley. I had to change out my original brakes for an old style brake which is not that effective. A disk brake would be preferable. The engine mounting rack consists of 1/2″ by 1/2″ square tubing welded to the bike frame. Here too you can see the rack off-set to align the drive pulley with the the wheel pulley. I’m able to pop the ‘V’ bent off the idler wheel and pedal. This helps eliminate a lot of extra friction when pedaling, especially when you run out of gas.

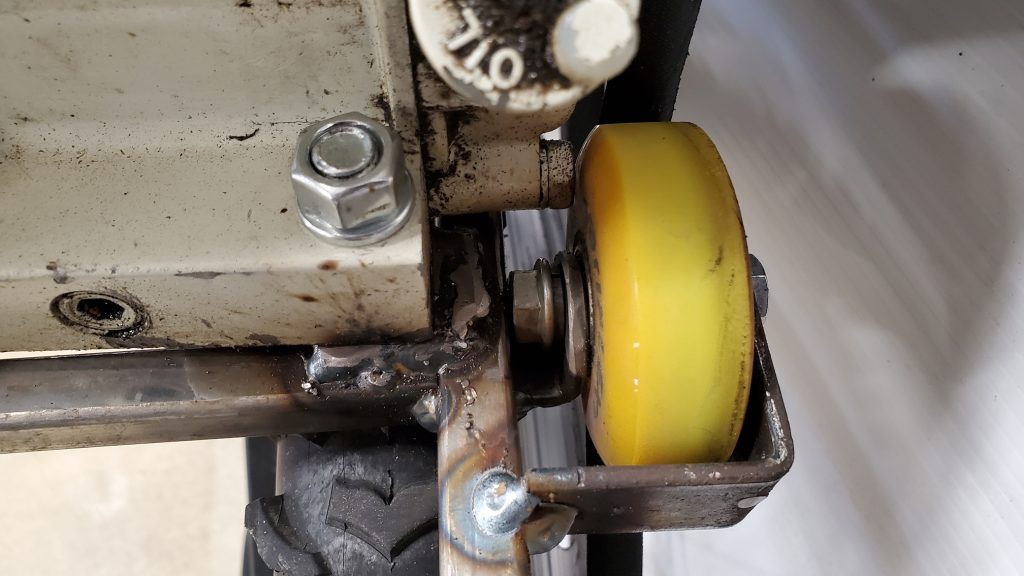

This roller blade wheel, which was turned and flattened on my drill-press, acts as the idler pulley. I chose this due to its high speed bearings. It was a tight fit but it works good.

An after market throttle was added using a long rear brake cable to bring it to the rear of the motor.

As mentioned the motor came off of an edger, which runs at a constant speed. I had to do some slight mods to the carburetor linkage to vary the throttle control. The tab above the spark plug shuts the motor off. One bottle carries gas while the other carries drinking water. I just have to remember which is which.