Not long ago I acquired a free 9 foot 160 pound double hull fiberglass Livingston boat. Unfortunately (or fortunately) it came without a trailer or wheels to move it around once on land. My truck has an 8 foot bed, and after taking some measurements I realized the boat could fit in the bed. The boat came with swinging wheel brackets (but no wheels) but were poorly attached to the rear transom. After looking up the cost of wheels and a used trailer, I figured I could make something that would work.

These are the ramps I came up with. I found two 4″ wide plastic boat trailer guide wheels at my local marine store, and purchased two 2×4’s, four 1×2’s, found some plywood scraps and a handful of screws. The guide wheels came with 3/4″ axle holes, but I found some PVC tubing laying around that worked as sleeves so I could use several 1/2″ bolts I had laying around. It helps to collect nuts, bolts and washers. Any hardware for that matter. My dad taught me that.

In this picture you can see the slight curved cut in the plywood just below the wheels that attach the tailgate. This rocker compensates for varying angles the ramps will encounter when loading and unloading.

Here you can see the 1/2″ plywood spacer added on the right to get the 4″ width I needed for the guide wheels. The hook shape in the plywood prevents the ramps from moving forward when loading the boat. To prevent the ramps from dropping off when unloading I try to push the ramp ends in the ground somewhat if there’s soft ground. If there’s pavement, I’m just keep my eye on any ramp movement. I cut the 1×2’s at an angle to create a trough that matched the bottom of the boat hull. Candle wax was rubbed in the wood grooves to make it easier when sliding the boat on the ramps. I also added index marks with a felt pen on the edge of the tailgate to get the proper spacing for the ramps.

The guide wheels were positioned a little higher than the top face of the 2×4’s making it a breeze once the boat keels hit the guide wheels.

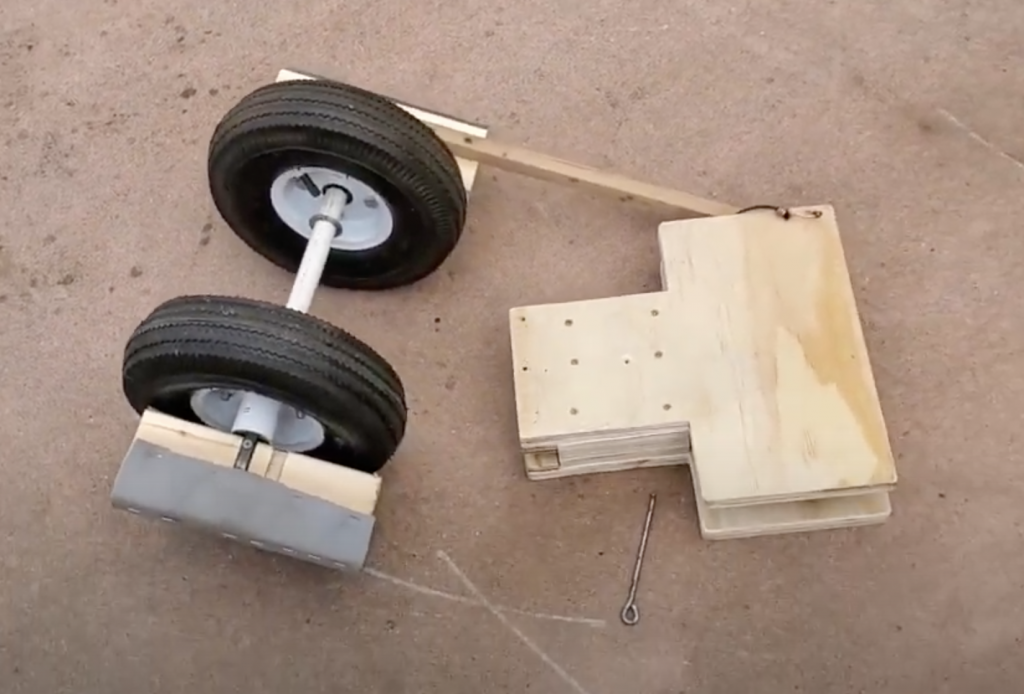

Here’s what I came up with to get the boat around once on land. This is a two part set-up held together by the steel pin. The section on the left is made up of two cheap Harbor Freight 10″ wheels and a length of 1/2″ square tubing screwed to two 2×4 blocks. PVC was used for spacers including large washers which were positioned to keep the tires from rubbing against the plywood ‘T’ section.

After taking the boat out of the truck I position these wheels a few feet under the boat. The slender wood handle helps me guide the wheels in place.

Piece of cake. And I have a bad back!

Here you can see the groves I added to the lengths of the 2×4 blocks. These are positioned to match the two keels. I stapled on some rubber sheeting to keep the wheels from slipping around when encountering sand or a rocky terrain. This is how the wheels travel around. I made it to fit snug on the boat transom.

Here it is being moved to the gated beach storage area.

Having removable wheels adds a bit of security to having a nefarious character easily walk off with your boat. I also cable lock the boat to the breakwater wall.