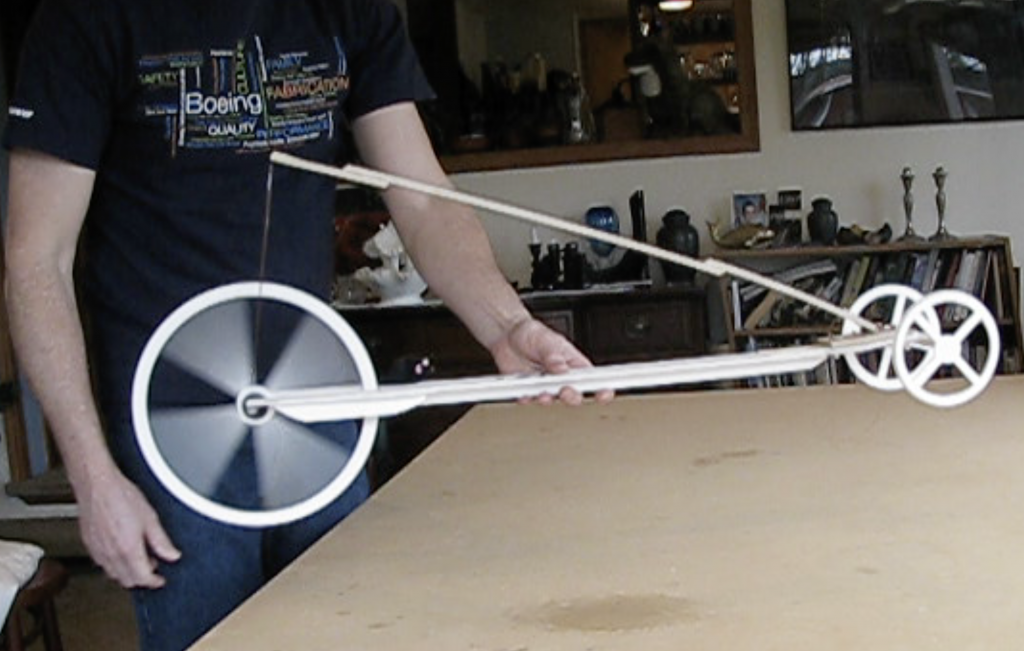

In my old shop at Boeing they use to have challenges to keep up moral. This was the mouse trap car challenge. Not for speed, but for distance.

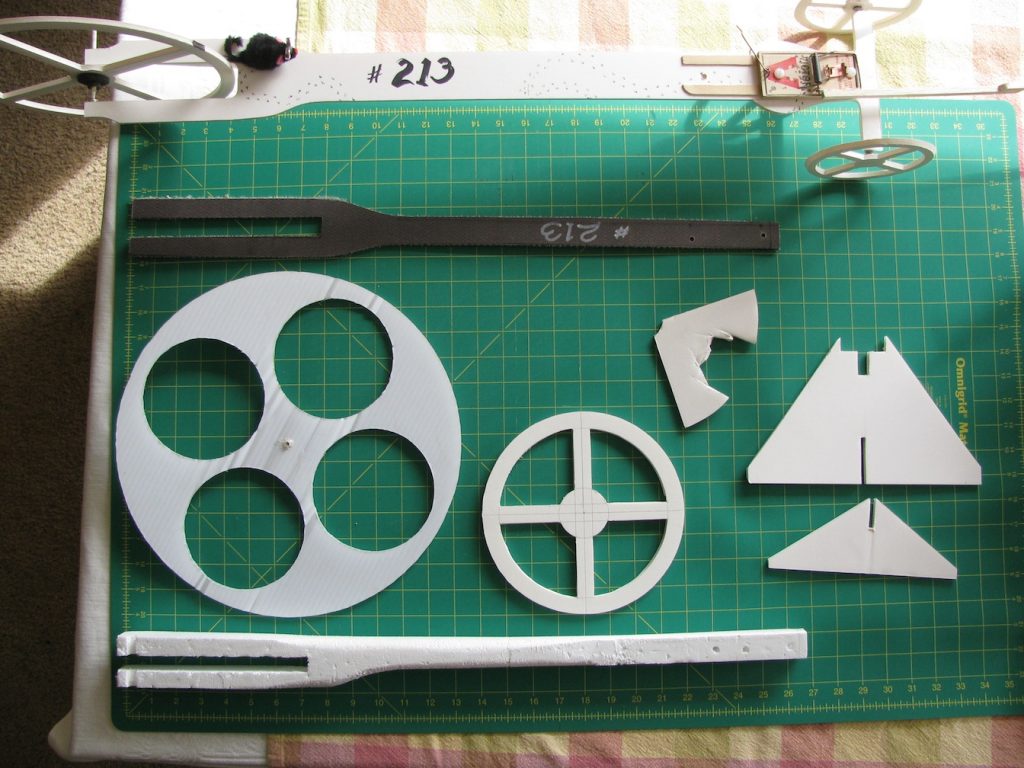

All the engineers and floor workers would compete. It was serious business. On the green mat are several materials I tried out before settling for foam board.

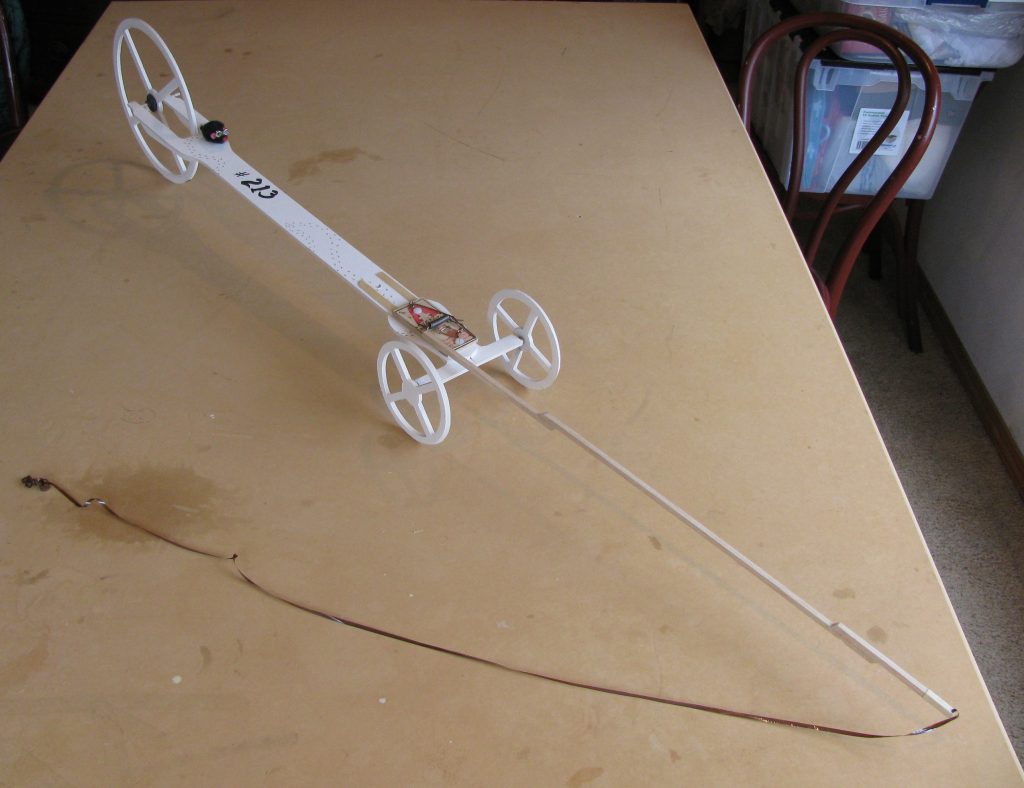

The glued on drive arm is a length of balsa wood. The drive line came from a cassette tape.

To get the car going I made this spiral foam drive cone. I start by wrapping the tape around the outside of the cone.

After the first wheel revolution it progresses down to the final high gear, the narrow axle to the right of the cone.

I lightly taped the cassette tape on the axle, making sure it released from the axe when it ran out.

If it stayed stuck to the axle, instead of coasting it would back the car up. Not good.

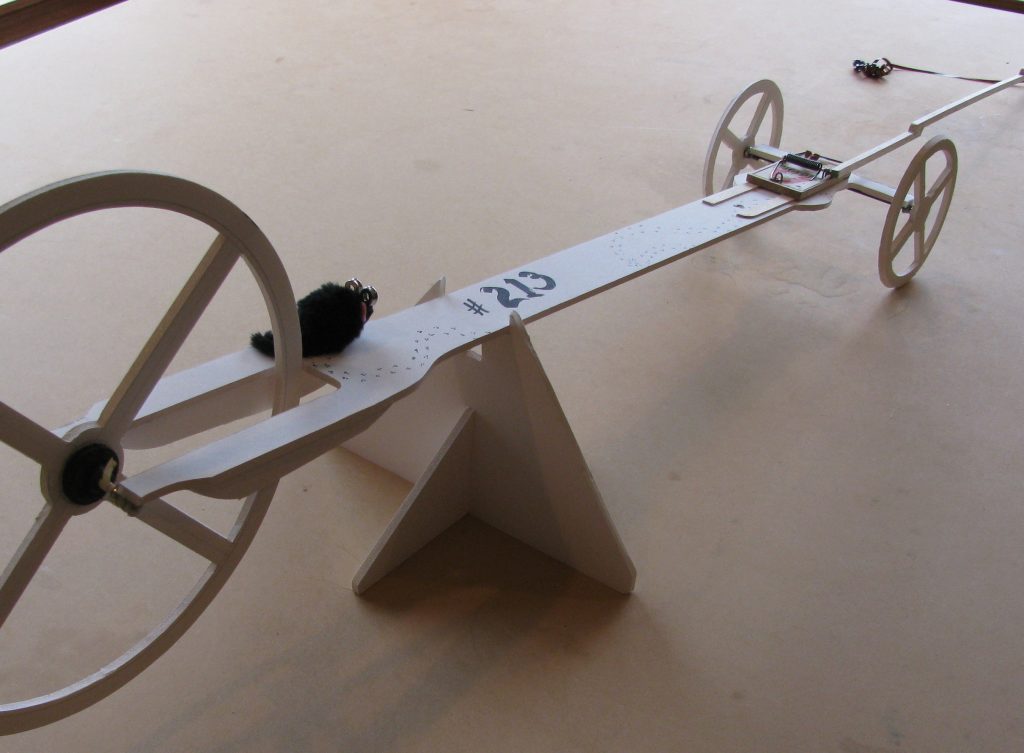

The outside of the wheels were grooved so just the edge rode on the ground. I figured less rolling resistance.

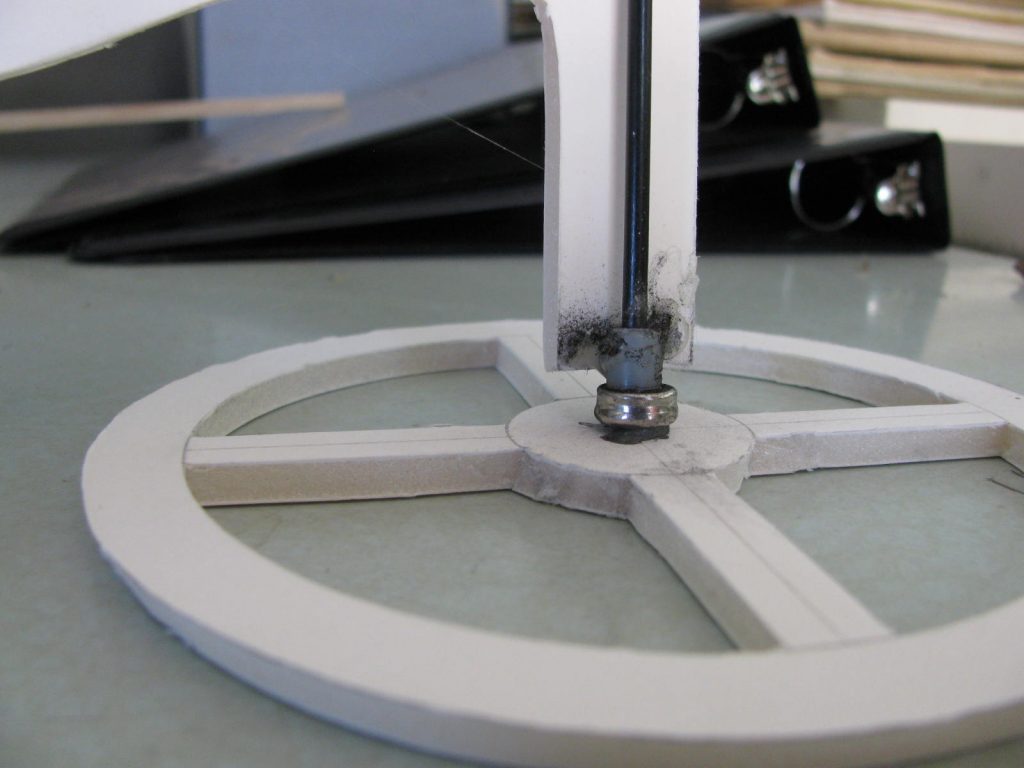

The graphite axle rode on delron plastic sleeves, hot glued onto the chassis. The black dust is graphite powder, used as an axle lubricant.

Here it is taking off. In test trials it went a total of 230 feet. Unfortunately come race day the race strip was so narrow I was unable to keep the car on course. Dam it Jim!